A Rube Goldberg Apparatus is a machine designed to perform a simple task in a very complex, over-engineered way. Most engineering projects consist of many subsystems which are designed and tested in parallel, and ultimately integrated into a complete system. In the first series of Freshman Design classes, Rube Goldberg machines were used to illustrate several important engineering concepts including project management, writing and document preparation, component testing and analysis, and system integration.

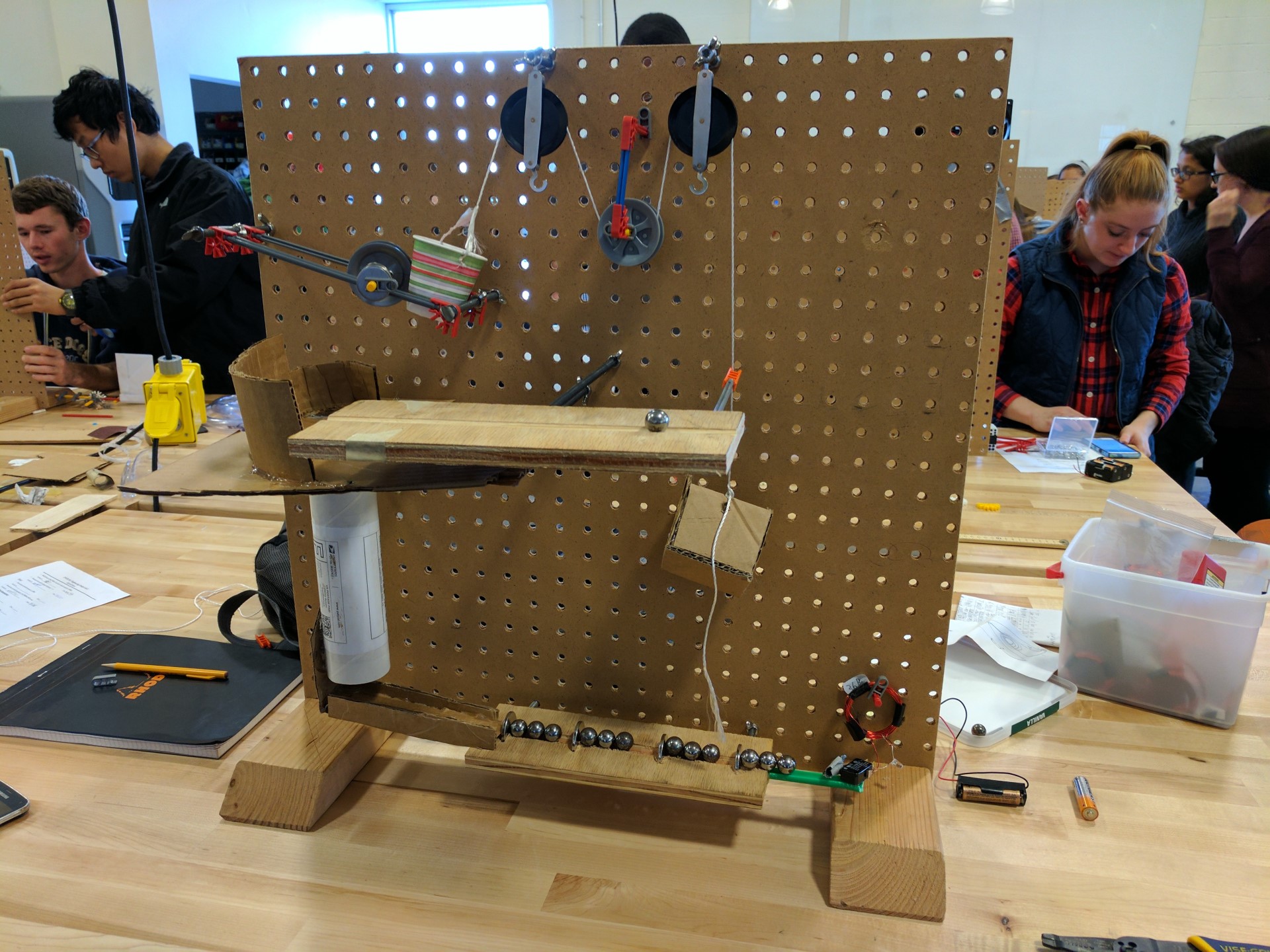

One design constraint that put a twist on the average Rube Golderberg machine is that this one had to be positioned vertically in two dimensions on the given peg-board. It also had to consist of at least four simple machines.

Our team successfully created this apparatus using four simple machines, as well as two uniquely designed machines. The apparatus started out with an inclined plane. A wheel rolling down this plane engaged a pully system, which was then connected to a lever. A drilled channel in the level created a rail for a steel marble on top of that lever to travel down. Once off the lever, the marble traveled down a screw, and was fed into a magnetic propulsion system. This system used the kinteic energy gained by the pull of the first magnetic field and transferred the gained momentum to each set of steel marbles, allowing the last one in each set to be shot off. Finally, the last steel marble hit a switch, which completed the circuit in a wireless, inductively couple system. When the circuit was completed, it turned an LED light on.